SeniorCitizen

Lawn Addict

- Joined

- Aug 28, 2010

- Threads

- 123

- Messages

- 2,108

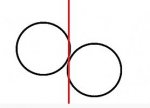

Possibly this pic will explain how overlap is accomplished without the non timed blades beating themselves to death.Bert- I never have heard of overlapping blades. You can't keep belt driven blades in time. No sorry, that's not right. There is a 1/8" gap between my 2 blade Zero, which is how I check then for running true etc.