Hello,

I am new to this forumn, but at my last straw. I have an Exmark Lazer-Z- I think it is a 2002-2003. It is a Diesel, Model No. L-Z27DD724.

I bought this machine used last year and it ran great- but at the end of the season it busted a mule drive belt (it has 2) and also the clutch was smoked. We have a shop and are very mechanically included, but not experts. In any case we replaced the clutch and serviced the machine. This season started out and we blew another belt- thought maybe it was a bad batch, so we replaced them again and they broke again. At this point I started replacing damn near everything.

We replaced every single deck and idler pulley and bearing on the machine, and then it continued to throw belts.

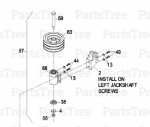

We then tore the deck off and replaced the entire spindle assemblies, new blades, replaced the jack shaft bearings. We did not replace the jack shaft or triple pulley because they looked good. And the machine continued to throw belts.

Then we talked with a dealer and they mentioned maybe there was wear in the deck itself so we replaced the deck struts, pins, etc- re mounted, balanced, and measured the deck- I thought for sure that would get it as it tightened up the deck a great deal- also put on brand new belts for good measure- within an hour of mowing it threw another belt.

I have spent more in parts and belts than the machine is worth probably 3 times over at this point. Does anyone have any other ideas what could be causing this? The only thoughts I have at this point is that maybe the jack shaft is actually bent, but it really does not appear to be at all- or possibly the rear mule belt idler arm and spring? It doesn't seem like it would cause it, but there is a bit of play.

The dealer is at a loss, and basically has no further ideas. Where the deck mounts and pins are- there was a tad bit of wear on the holes on the deck (a bit egg shaped) but we are talking barely at all- I can't imagine it would be enough to cause the problem.

I am new to this forumn, but at my last straw. I have an Exmark Lazer-Z- I think it is a 2002-2003. It is a Diesel, Model No. L-Z27DD724.

I bought this machine used last year and it ran great- but at the end of the season it busted a mule drive belt (it has 2) and also the clutch was smoked. We have a shop and are very mechanically included, but not experts. In any case we replaced the clutch and serviced the machine. This season started out and we blew another belt- thought maybe it was a bad batch, so we replaced them again and they broke again. At this point I started replacing damn near everything.

We replaced every single deck and idler pulley and bearing on the machine, and then it continued to throw belts.

We then tore the deck off and replaced the entire spindle assemblies, new blades, replaced the jack shaft bearings. We did not replace the jack shaft or triple pulley because they looked good. And the machine continued to throw belts.

Then we talked with a dealer and they mentioned maybe there was wear in the deck itself so we replaced the deck struts, pins, etc- re mounted, balanced, and measured the deck- I thought for sure that would get it as it tightened up the deck a great deal- also put on brand new belts for good measure- within an hour of mowing it threw another belt.

I have spent more in parts and belts than the machine is worth probably 3 times over at this point. Does anyone have any other ideas what could be causing this? The only thoughts I have at this point is that maybe the jack shaft is actually bent, but it really does not appear to be at all- or possibly the rear mule belt idler arm and spring? It doesn't seem like it would cause it, but there is a bit of play.

The dealer is at a loss, and basically has no further ideas. Where the deck mounts and pins are- there was a tad bit of wear on the holes on the deck (a bit egg shaped) but we are talking barely at all- I can't imagine it would be enough to cause the problem.